SUSU developers have patented a unique pneumatic locking device to prevent the release of aggressive gases from metallurgical plants. It will make the production process safer for industrial personnel and the environment.

In chemical and such types of metallurgical production as blast furnace, steelmaking and ferroalloy, one of the main operations is loading bulk materials (charge) into the furnace. The side effect is that this operation is a source of pollution of the atmosphere and water bodies. Ferrous metallurgy enterprises account for up to 50% of total atmospheric pollution (more than 10.3 million tons of hazardous substances per year). Dust and gas emissions from the furnace are generated when while loading the charge, the mechanical locking device is open, and chemical reactions occur under pressure above atmospheric one, what leads to the release of aggressive gases through the loading device itself outwards.

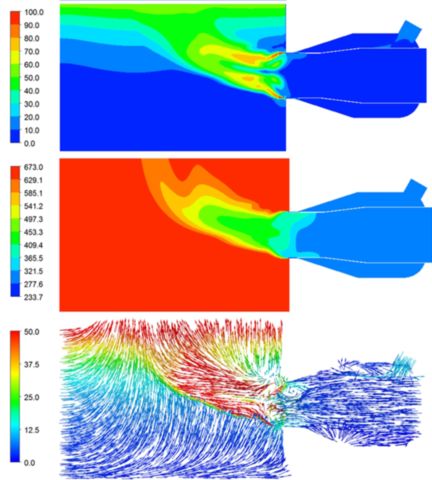

To solve this environmental problem, scientists from South Ural State University have developed a pneumatic vortex-type locking device that will prevent the release of aggressive gases by countercurrent gas under pressure equal to or exceeding the pressure in the reactor.

"We removed the mechanical shutter from the construction of the industrial furnace and placed a guide apparatus around the bulk materials loading channel, with fixed blades located at an angle," says Daria Khabarova, Associate Professor at the SUSU Department of Hydraulics and Hydraulic and Pneumatic Systems. "The compressor directs a flow of air under pressure to this guide apparatus, what results in a vortex flow of incoming air. The air vortex blocks the loading channel, from where aggressive gases are usually released in the opposite direction. That is, the bulk material, by the worker’s efforts, still enters the reactor cavity, but at the same time, the loading channel zone over its entire area is locked by a vortex, what prevents the release of hazardous gas into the human working space."

The researchers calculated that when the charge enters the furnace from the mechanical shutter, the entire volume (100%) of aggressive gases is released outwards. The use of a pneumatic vortex-type locking device will completely eliminate emissions of dust and corrosive gases into the workshop, and reduce the amount of total emissions into the atmosphere by 50 times (a small part of the gases (2%) inevitably leaks through the gaps from the mechanism during the operation of the furnace). In addition, there is no need for an autonomous gas cleaning system, and the service life of the filling apparatus increases. The new device makes it possible to facilitate and speed up the process of loading bulk material into the furnace since the velocity component of the air/gas entering the reactor carries the charge along with it.

The equipment has a simple design and is made of heat-resistant ceramics without moving parts, which makes it safe, durable and capable of non-stop operation. Such a pneumatic device for locking the furnace reactor is already used at the Cherepovets Metallurgical Plant. The absolute uniqueness of the development is that the world metallurgy has not yet known locking devices based on the pneumatic principle.

The Decree of the Government of the Chelyabinsk Region approves the State Program of the Chelyabinsk Region for 2021–2025 "Environmental Protection in the Chelyabinsk Region". The project was developed by university scientists in accordance with the subprogram "Protection of Atmospheric Air in the Chelyabinsk Region", the main goal of which is to create conditions for the introduction of the Best Available Technologies (BAT) to reduce emissions of hazardous substances (pollutants) into the atmospheric air from industrial enterprises of the Chelyabinsk Region.