ChTZ-URALTRAK (Chelyabinsk Tractor Plant) is part of the Russian defence industry complex, and it mainly produces dual-purpose diesel engines with the capacity of up to 1500 hp. The plant is currently solving an important problem on increasing the capacity of a series-production engine, while not making it heavier or leading to losses in its service life. Forcing of the engine inevitably entails increased loads on the main parts, components and units. It is more practical to maintain the strength of parts under increased loads by replacing structural materials with modern and higher-strength ones.

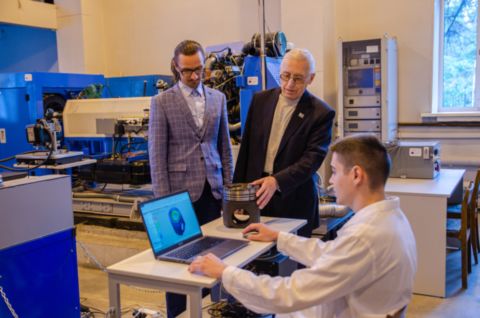

In 2022, ChTZ addressed South Ural State University to jointly solve this problem with research teams of the Materials Science and Automotive Engineering subdivisions of the Institute of Engineering and Technology.

.jpg)

As part of the Fundamentals of the Synthesis and Operation of Non-conventional Materials strategic project under the Priority 2030 program, the development and selection of materials for such engine parts as piston, crankshaft and exhaust valve were conducted. New materials can be used under conditions of elevated temperatures, forces and pressures without losing their mechanical properties.

“The development of new materials with improved mechanical characteristics at high temperatures for parts of an advanced internal-combustion engine is a complex fundamental task that required thermodynamic modelling of alloy compositions, and conducting of metallographic survey and mechanical tests,” says Director of the SUSU Institute of Engineering and Technology Mikhail Ivanov. “In order to solve the problems set by the plant, an interdisciplinary team with invited specialists from MISIS National University of Science and Technology and staff members of the SUSU Institute of Engineering and Technology was formed. Currently, experimental melting of materials has been carried out and their properties have been assessed. It is planned to move on to creating prototypes of engine parts for bench testing.”

The work will continue with addressing the issues related to the introduction of new structural materials into the ChTZ technological process. The first step towards this has already been taken: in particular, a new ion nitriding section was opened at the enterprise on February 1st.